Category: 2013-2014

Archive of all student posts from 2013/14

wk 2 – clay and brick tiles Buster Rönngren

271113

Tottenham Court Road Station – Laing O’Rourke Construction Ltd; and Lend Lease Construction; Dr. Sauer Group (Consultant); architect TBC.

Concrete cast in-situ, loadbearing walls with columns – panels of 2×2 meters, 40 cm thick. Columns – steel sections needs to be inserted in the columns; columns cast in steel molds

Concrete – ready mixed (mix TBC); 24 hour cure

http://www.nce.co.uk/features/geotechnical/precision-piling/8624010.article

Anton Gorlenko, Fitzroy Place

Week 2 – Site photo- Zsuzsa Peter

Leandenhall Building

Architect: Richard Rogers

Structural Engineer: Arup

Contractor: Laing O’Rourke

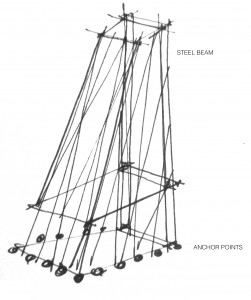

The material used for the structure is prefabricated steel beams which are transported to the site (you can see on the photo the method trough which these beam are carried further inside the building). The beams are cast in a I shape. The choice of using steel beams for the structure instead of concrete is probably motivated by the desire to create a free floor space which is relatively small in comparison to the building’s height, the beams being anchored on the perimeter of the building into the ground.

timelapse of the building process: http://vimeo.com/67882670

Week 2 – Site Photos – Andrew Yuen

Project: Riverlight Residential Blocks, Nine Elms

Architect: Rogers Stirk Harbour + Partners

Structural Engineer: Ramboll

Building component: Metal/steel structural frame with diagonal bracing

Material: Reinforced Concrete

The reinforced concrete is used as the main material to manufactured the floor plates, in the area of 620000 sq. feet. The floor plates (slab) are produced in the factory with the method of casting, before they are transferred to the site for assembling process.

Concrete is a mixture of coarse and fine aggregates with a paste of portland cement and water as a binder material. The material itself has a high degree of hardness, good thermal compatibility which will not cause unacceptable stresses in response to the change of temperatures and good durability that resists corrosion. However, low tensile strength and ductility are the main weaknesses of the material. By casting in reinforce components such as steel, it overcome the mentioned problems.

Week 2 – Michael Cheung

Blackfriars station: Architect – Pascall + Wilson Architects

Engineer – Jacobs and Tony and Gee and Partners

Contractor – Balfour Beatty

Building component: Steel I beam – component is used in bending.

Material properties: Bending is caused by compression and tension on opposing surfaces of a material – the further these two forces are, the less bending there is. The I beam increases the distance between these two surfaces with minimal material. Steel is malleable and flexible, making it suitable to be placed under bending. It also makes the manufacture of the ‘I’ shape easier, as a solid steel beam can be hot rolled on either side.

Week Two – Natalie

Week 2_Hye Rim Lee

*British musuem World Conservation and Exhibitions Centre (17,000m2), Rogers Stirk Harbour + Partners, Arup (setcvice) and

Ramboll UK (structural), Mace

*glass and stone – spans in between glass/stone in-situ steel frames –10/50mm thick and no more than 5m by 5m

*Precast glass rainscreen panel (silicon dioxide (SiO 2), sodium carbonate ( Na 2 CO 3) )/rainscreens of shell fragment-saturated

Roach stone – precast/cut in factory and transported to site – strength: 4.5N/mm2 / 45N/mm2 – density: 2,579 kg/m3 / 2,195 kg/m3

– 72h curing in glass mould